Column Farma

Column Farma Specification

- Constitute

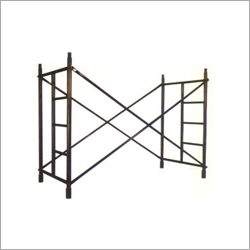

- Mainframe frame, connector sleeve, support props

- Weight

- Depends on size and configuration

- Prop Head

- Universal adjustable head

- Technique

- Precision Fabrication

- Pin

- Heavy-duty locking pins

- Color

- Blue or as per order

- Sleeve size

- Available in multiple size options

- Features

- Easy assembly, robust, corrosion resistant

- Product Type

- Scaffolding Column Formwork

- Material

- Premium Steel

- Components

- Column Farma accessories

- Diameter

- Adjustable, as per requirement

- Width

- Standard size or customizable

- Length

- Standard or Custom

- Height

- Adjustable

- Thickness

- Optimal Sheet Thickness (varies with height)

- Platform Loading Capacity

- High load bearing capacity

- Surface Treatment

- Painted / Galvanized

- Application

- Concrete column forming for construction

- Size

- Custom sizes available

- Service Life

- Long service durability

- Environmental Resistance

- Suitable for outdoor use

- Packing

- Standard export packaging

- Maintenance

- Low maintenance required

- Formwork Type

- Reusable Modular System

- Edge Protection

- Rounded safe finish

- Load Class

- Meets industrial safety standards

- Connection Type

- Welded and bolted joints

Column Farma Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

About Column Farma

Key Features:

- Resistant to heat

- Easy installation

- Fine finish

- Excellent durability

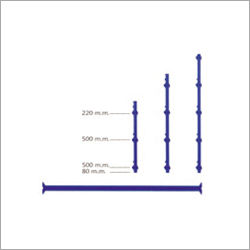

Technical specification

| Material Used For Column | |

| 14 G.M.S. SHEET AND 45 x 45 x 5th angle with heavy stiffner suppot | |

| Column Farmas Available in All Sizes | |

| Like 250 to 1000m.m | height 1200 to 3000m.m |

Versatile Modular System for Construction

Column Farma offers a reusable modular system tailored for concrete column forming, ensuring flexibility on every construction site. With adjustable diameter, height, and customizable sizes, it meets various project specifications. Its optimal sheet thickness, robust mainframe, and universal support props allow high load bearing, making it ideal for demanding industrial applications.

Enhanced Safety and Durability

The product includes rounded edge protection and heavy-duty locking pins to maximize worker safety during assembly and use. Manufactured from premium steel and finished with painted or galvanized surfaces, Column Farma withstands outdoor elements, provides excellent corrosion resistance, and guarantees a long service life.

FAQs of Column Farma:

Q: How is the Column Farma system assembled for use on-site?

A: Column Farma uses easy-to-assemble modular components, including a mainframe, connector sleeve, support props, and universal adjustable heads. Welded and bolted joints, along with heavy-duty locking pins, ensure that each section is securely connected, enabling quick installation and efficient workflow on site.Q: What are the benefits of using a reusable modular system like Column Farma?

A: The reusable modular design enables swift setup and dismantling, reducing labor time and costs. It offers flexibility with adjustable diameter, height, and customizable size options, supporting various column specifications for construction, making it both economical and adaptable for repeated projects.Q: When is it recommended to use Column Farma in construction projects?

A: Column Farma is best suited during the column forming stages of concrete construction. Its high load capacity, robust structure, and outdoor resistance make it ideal for both industrial-scale and general building projects requiring durable and reliable formwork systems.Q: Where can Column Farma be utilized most effectively?

A: This system is effective on construction sites where concrete columns need forming, such as commercial buildings, bridges, and industrial projects. Its adaptability and strong components allow use in outdoor environments and challenging site conditions across India.Q: What is the process for maintaining Column Farma accessories and components?

A: Column Farma requires low maintenance due to its corrosion-resistant steel and precision surface treatments. Cleaning with water and periodic inspections for wear or damage are sufficient to maintain optimal condition over its extended service life.Q: How do the adjustable features of Column Farma benefit the construction process?

A: Adjustable diameter, height, and sleeve sizes allow precise customization for each project, accommodating a wide range of concrete column specifications. This ensures efficient resource use, minimizes waste, and supports project timelines by fitting various architectural requirements.Q: What safety measures are built into the Column Farma design?

A: Safety is addressed through rounded edge protection, universal adjustable heads, and robust locking pins, reducing injury risk during handling and assembly. Compliance with industrial safety standards further assures a secure working environment on-site.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Building Centering Material Category

Telescopic Span

Minimum Order Quantity : 1 Unit

Constitute : other, Made of two telescoping pipes for variable length

Color : Blue or as per requirement

Pin : Other, Forged or hightensile steel pin for locking adjustment

Components : Other, Outer Tube, Inner Tube, Jack Nut, Bottom Plate, Prop Pin

Platform Loading Capacity : Up to 4 tons per span

Adjustable Props

Minimum Order Quantity : 1 Unit

Constitute : other, Mild steel tubes and high strength fittings

Color : Blue / Red / Customized

Pin : Other, Cast iron or steel prop pin

Components : Other, Inner tube, Outer tube, Threaded collar, Prop nut, Base plate, Head plate, Lock pin, Prop sleeve

Platform Loading Capacity : 1.5 to 3 Tons (Varies by model and extension length)

Tubular Scaffolding Fittings

Minimum Order Quantity : 1 Unit

Constitute : other, Mild Steel/Carbon Steel parts

Color : Silver, Blue, or Customized

Pin : Other, Steel pins for secure locking

Components : Other, Base Plate, Swivel Coupler, Fixed Coupler, Sleeve Coupler, Drop Forge Clamps, Joint Pins

Platform Loading Capacity : Up to 300 kg/sq.m (varies by configuration)

Scaffolding Cuplock System

Minimum Order Quantity : 1 Unit

Constitute : other, Steel Tubes with Welded Cups and Blades

Color : Blue, Silver, or Customized

Pin : Other, Included on Standards for Proper Alignment

Components : Other, Vertical Standard, Ledger, Diagonal Braces, Base Plate, Top Cup, Bottom Cup

Platform Loading Capacity : Up to 150 kg/m

Send Inquiry

Send Inquiry