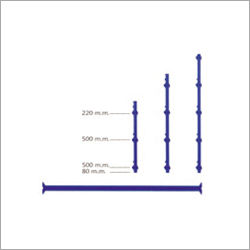

Telescopic Span

Telescopic Span Specification

- Sleeve size

- Standard sleeve size for adjustment

- Features

- High strength, corrosion resistant, easy to install, reusable

- Pin

- Forged or high-tensile steel pin for locking adjustment

- Weight

- 25-42 kg depending on size

- Technique

- Welded construction using CO2/MIG welding

- Color

- Blue or as per requirement

- Prop Head

- Heavy-duty prop head

- Constitute

- Made of two telescoping pipes for variable length

- Product Type

- Adjustable Telescopic Span

- Material

- Mild Steel (IS 1161/1239 Grade)

- Components

- Outer Tube, Inner Tube, Jack Nut, Bottom Plate, Prop Pin

- Diameter

- 48 mm outer / 40 mm inner (approx.)

- Width

- Variable as per model

- Length

- 1.75 m to 4.75 m (adjustable)

- Height

- Adjustable as per the span type

- Thickness

- 3.0 mm to 5.0 mm

- Platform Loading Capacity

- Up to 4 tons per span

- Surface Treatment

- Painted/Hot Dip Galvanized

- Application

- Formwork & slab supporting in civil construction

- Size

- Available in standard and customized sizes

- Maintenance

- Low maintenance, rust preventive ends

- End Plate Size

- 150 x 150 mm approx.

- Compatibility

- Compatible with standard formwork systems

- Packing Type

- Loose or packed (as per client)

- Tensile Strength

- Designed for demanding load requirements

- Adjustment Mechanism

- Threaded jack nut and pin

- Usage

- Heavy Duty Construction Support

Telescopic Span Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

About Telescopic Span

Serving the varied needs of construction and related industries, we feel immense pleasure to introduce our company as prime manufacturer and supplier of the best quality Telescopic Span. With due perfection, our deft professionals manufacture this span as per the set market guidelines with the use of optimum quality raw materials. Widely used for supporting loaders as well as crane elongation, this span is applicable in construction sites. Available in various shapes, lengths and dimensions, this Telescopic Span is known for hassle free handling.

Key Features:

- High load bearing capacity

- Application specific structure

- Robust construction

- Excellent handling

Specification :

| Span Size Extension(Mtr.) | ||

| | Min. | Max. |

| ESO - ESI | 1.75 | 2.70 |

| SO - ESI | 2.40 | 3.45 |

| SO - SI | 2.40 | 4.10 |

| SO - SI | 3.05 | 4.7 |

Precision Engineered for Heavy Duty Support

Designed to meet the rigorous demands of civil construction, the telescopic span utilizes high-quality mild steel and advanced welding techniques for superior strength. Adjustable length and variable widths ensure versatility, while the prop head and secure locking pins maintain stability under heavy loads, making it ideal for formwork and slab support.

Adaptable and Easy to Install

The threaded jack nut and standard sleeve mechanism enable quick and secure adjustments during installation. With compatibility across major formwork systems and options for loose or packed delivery, users benefit from a flexible solution that requires minimal effort for setup and ongoing use, optimized for construction sites across India.

Maintenance and Corrosion Resistance

With low-maintenance rust preventive ends and a painted or hot-dip galvanized finish, this telescopic span is built to withstand harsh site conditions. Its resilience reduces replacement frequency, lowering operational downtime and maintenance costs for contractors and builders.

FAQs of Telescopic Span:

Q: How does the threaded jack nut and pin mechanism facilitate span adjustment?

A: The threaded jack nut and pin mechanism allows precise length and height adjustments. By turning the jack nut and inserting the pin, users can securely lock the telescopic pipes in place, ensuring stable support tailored to site requirements.Q: What is the process to install the telescopic span in formwork applications?

A: Installation involves positioning the outer and inner tubes at the required span, adjusting the length using the jack nut and pin, and securing the prop head under the slab or formwork. The robust construction allows for straightforward placement and ensures reliable support.Q: Where can this telescopic span be used in construction?

A: This span is predominantly used in civil construction for supporting formwork and slabs. Its adjustable design and high strength make it suitable for a variety of building sites, infrastructure projects, and any scenario needing heavy-duty support.Q: When should maintenance be performed on these spans?

A: Routine inspection for surface integrity and mechanical function is recommended, especially before and after major projects. Thanks to rust preventive ends and durable finishes, maintenance requirements are minimal compared to conventional alternatives.Q: What are the advantages of choosing a model with a painted or hot dip galvanized finish?

A: Both finishes provide enhanced corrosion resistance. Hot dip galvanized spans offer superior protection in aggressive environments, whereas painted versions are suitable for standard site conditions and allow color customization according to client requirements.Q: What benefits do the telescopic spans engineered features offer for demanding load requirements?

A: With a platform loading capacity of up to 4 tons per span, reinforced by CO2/MIG welded construction and high-tensile components, the telescopic span ensures safe and dependable load-bearing performance in demanding construction projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Building Centering Material Category

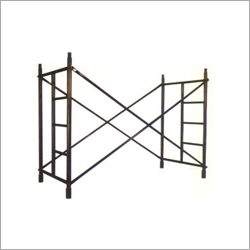

Scaffolding Cuplock System

Minimum Order Quantity : 1 Unit

Size : Modular sizes available

Material : Other , High Tensile Steel

Weight : 10 kg 18 kg per component (varies by size)

Height : Customized as per requirement

Components : Other, Vertical Standard, Ledger, Diagonal Braces, Base Plate, Top Cup, Bottom Cup

Column Farma

Minimum Order Quantity : 1 Unit

Size : Custom sizes available

Material : Other , Premium Steel

Weight : Depends on size and configuration

Height : Adjustable

Components : Other, Column Farma accessories

Adjustable Props

Minimum Order Quantity : 1 Unit

Size : Standard: 2m x 3.5m (custom sizes available)

Material : Other , High grade Mild Steel

Weight : 12 18 kg (varies per prop size)

Height : Adjustable as per site requirements

Components : Other, Inner tube, Outer tube, Threaded collar, Prop nut, Base plate, Head plate, Lock pin, Prop sleeve

Tubular Scaffolding Fittings

Minimum Order Quantity : 1 Unit

Size : Adjustable sizes as per requirement

Material : Other , Mild Steel, ISI Marked or equivalent standard

Weight : Varies (ex: 1.2 kg 2.5 kg depending on fitting type)

Height : Standard & customizable options

Components : Other, Base Plate, Swivel Coupler, Fixed Coupler, Sleeve Coupler, Drop Forge Clamps, Joint Pins

Send Inquiry

Send Inquiry