Scaffolding Cuplock System

Scaffolding Cuplock System Specification

- Pin

- Included on Standards for Proper Alignment

- Color

- Blue, Silver, or Customized

- Constitute

- Steel Tubes with Welded Cups and Blades

- Features

- High Load Capacity, Quick Erection & Dismantling, Corrosion Resistant, Robust Construction

- Sleeve size

- 150 mm standard sleeve

- Technique

- Hot Rolled, Welded Construction

- Weight

- 10 kg 18 kg per component (varies by size)

- Prop Head

- Cup Head

- Product Type

- Scaffolding Cuplock System

- Material

- High Tensile Steel

- Components

- Vertical Standard, Ledger, Diagonal Braces, Base Plate, Top Cup, Bottom Cup

- Diameter

- 48.3 mm

- Width

- Varies by platform, typically 1.2 m to 1.5 m

- Length

- 0.6 m to 3.0 m

- Height

- Customized as per requirement

- Thickness

- 3.0 mm to 4.0 mm

- Platform Loading Capacity

- Up to 150 kg/m

- Surface Treatment

- Hot Dip Galvanized / Painted

- Application

- Construction, Maintenance, Industrial, and Structural Access

- Size

- Modular sizes available

- Cup Material

- Malleable Casting Iron

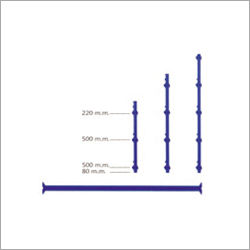

- Standard Spacing

- 500 mm, 1000 mm, 1500 mm, and 2000 mm

- Standards Ends

- Forged Blades for Positive Locking

- Compliance Standard

- Conforms to EN12810 / EN12811 & IS Standards

- Usage Environment

- Outdoor & Indoor, All Weather

- Ledger Spacing

- Horizontal spacing 1.0 m to 2.5 m

- Connection Type

- Auto-locking Cup Mechanism

- Temperature Resistance

- -30°C to +60°C

- Storage

- Stackable for Efficient Storage

Scaffolding Cuplock System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

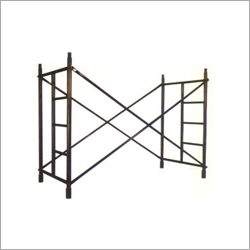

About Scaffolding Cuplock System

In respective field, our deep-rooted organization is engrossed in manufacturing and supplying a huge assortment of striking Scaffolding Cuplock System. The offered system is generally demanded in construction, marine, maintenance, shipping and other applications to support the architecture of any building. Also, used as a permanent base for construction purpose, this system is manufactured with the use of quality assured raw materials at our sophisticated production set up. Moreover, clients can purchase this Scaffolding Cuplock System in various specifications at highly competitive prices from us.

Key Features:

- Robust construction

- High strength

- Easy to install

- Offers strong support

Technical specification

| Vertically : |

|

| Sizes | Wt. (Approx) |

| 3.00m | 15.0 kgs. |

| 2.50m | 12.5 kgs. |

| 2.00m | 10.0 kgs. |

| 1.50m | 7.5 kgs. |

| 1.00m | 5.0 kgs. |

| 0.50m | 2.5 kgs. |

| Horizontal are available in following Sizes | |||||

| Sizes | Wt.(Approx) | Sizes | Wt.(Approx) | Sizes | Wt.(Approx) |

| 2.50 m | 9.5 kgs. | 1.80 m | 6.5 kgs. | 1.25 m | 4.5 kgs. |

| 2.00 m | 7.5 kgs. | 1.50 m | 5.5 kgs. | 1.00 m | 4.0 kgs. |

Robust Auto-Locking Mechanism

This Cuplock system utilizes an auto-locking cup mechanism, enabling swift assembly and enhanced safety. Forged blades and malleable iron cups provide secure connections that withstand heavy loads and demanding environments. Positive locking reduces the risk of accidental disengagement, making it especially suitable for dynamic site conditions.

Versatile Spacing & Modular Flexibility

With adjustable vertical and ledger spacing, this scaffolding system suits a wide range of project requirements. The modularity allows customization for specific heights, widths, and loading capacities, making it ideal for diverse construction and maintenance tasks, both indoors and outdoors.

Superior Material & Weather Resistance

Engineered from high tensile steel and finished with hot dip galvanization or high-quality paint, the Cuplock system delivers excellent resistance to corrosion and weathering. Its temperature tolerance from -30C to +60C guarantees reliable performance in all climates, ensuring long-term durability and service life.

FAQs of Scaffolding Cuplock System:

Q: How does the auto-locking cup mechanism improve scaffolding assembly?

A: The auto-locking cup mechanism streamlines assembly by allowing components to be rapidly engaged and securely locked in place. This reduces setup time, enhances worker safety, and ensures stable connections for various load conditions.Q: What spacing options are available for this Cuplock system, and how do they affect usage?

A: Standard vertical spacings of 500 mm, 1000 mm, 1500 mm, and 2000 mm are available, with horizontal ledger spacings ranging from 1.0 m to 2.5 m. These options provide flexibility in creating platforms of varying widths and heights to suit specific construction or maintenance tasks.Q: When should this Cuplock scaffolding system be deployed on site?

A: This system is ideal for use during the initial stages of structural works, facade installation, maintenance procedures, or any scenario requiring temporary and secure access. Its robust design supports frequent erection and dismantling cycles.Q: Where can the Cuplock scaffolding system be used?

A: Designed for both outdoor and indoor environments, this system performs effectively in construction sites, industrial facilities, maintenance projects, and locations with harsh weather conditions due to its excellent temperature and corrosion resistance.Q: What is the process for erecting and dismantling the Cuplock scaffolding system?

A: Assembly involves positioning the vertical standards, connecting ledgers and braces using the auto-locking mechanism, and installing base plates for stability. Dismantling is quick, as components can be rapidly unlocked and stacked for storage, optimizing project times and logistics.Q: Which benefits does this Cuplock system offer over conventional scaffolding types?

A: Key advantages include quick and safe assembly, high load capacity (up to 150 kg/m), corrosion resistance, modular flexibility, efficient stacking for storage, and compliance with international safety standards, making it a preferred choice for professional use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Building Centering Material Category

Telescopic Span

Minimum Order Quantity : 1 Unit

Pin : Other, Forged or hightensile steel pin for locking adjustment

Height : Adjustable as per the span type

Color : Blue or as per requirement

Size : Available in standard and customized sizes

Product Type : Other, Adjustable Telescopic Span

Column Farma

Minimum Order Quantity : 1 Unit

Pin : Other, Heavyduty locking pins

Height : Adjustable

Color : Blue or as per order

Size : Custom sizes available

Product Type : Other, Scaffolding Column Formwork

Adjustable Props

Minimum Order Quantity : 1 Unit

Pin : Other, Cast iron or steel prop pin

Height : Adjustable as per site requirements

Color : Blue / Red / Customized

Size : Standard: 2m x 3.5m (custom sizes available)

Product Type : Other, Adjustable Steel Scaffolding Prop

Tubular Scaffolding Fittings

Minimum Order Quantity : 1 Unit

Pin : Other, Steel pins for secure locking

Height : Standard & customizable options

Color : Silver, Blue, or Customized

Size : Adjustable sizes as per requirement

Product Type : Other, Tubular Scaffolding Fittings

Send Inquiry

Send Inquiry